News

For a sustainable handling of ressources, Wyco-Glas uses renewable energies. Our energy consumption is partly satisfied through solar energy of solar cells. We further recycle our acrylic glass and polycarbonate cutting leftover and use it for the production of new material, e.g. injection moulding raw material.

Also we refrain from christmas presents for our costumers and use the amount to donate it for nonprofit organisations.

Flexibility

Time flexibility: The ideal image of every entrepreneur is a client that orders in the long term/early. This, however, is not always possible. In urgent cases we can usually produce at short notice.

Easy handling: In our display area we have different samples. This helps us in explaining and demonstrating processing possibilities easily and quickly.

Manufacturing spectrum: The many materials and processing possibilities enable us to realize even unusual ideas.

Individual Production

We manufacture individually for you based on your draft, sketch, sample or data.

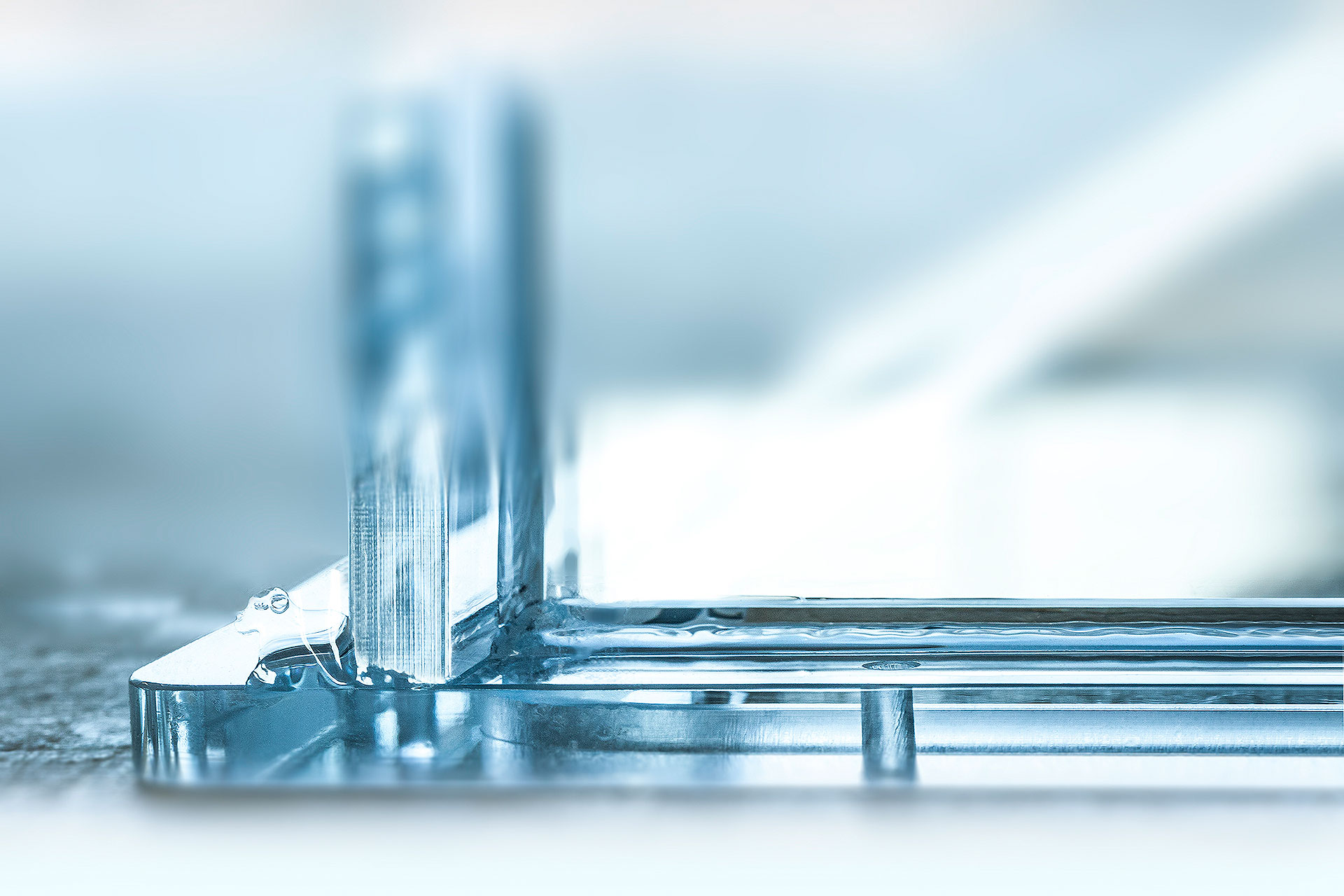

We produce your unique piece, sample, small series and series parts for technical and design oriented purposes using acrylic glass (PLEXIGLAS®), polycarbonate (MAKROLON®) and many other synthetic material. Feel free to contact us. Our multiple processing possibilities such as laser cutting, CNC milling, complete transforming, adherence etc. allow us to realize simple as well as complex drafts.

Senden Sie uns gerne Ihre Request, die wir schnellstmöglich für Sie bearbeiten.

Downloads

Plastic Material

Especially Wyco-Glas' primarily processed material PLEXIGLAS® offers - due to its unequalled transperancy (92%) - the ideal conditions for the production of high-end products.

Ideal fields of application are exhibitions, fairs, museums, art, design, technology, electronics etc. In addition to the transparent material, there is also coloured material with high-gloss or satined surface.

There are diverse options of in-house processing, from lasering and CNC milling to complete thermal conversion.

In our production samples section, you will get an insight into a selection of our manufactured objects.

Reliable partner for demanding industries

Since 1932 we have been a flexible and reliable service provider for demanding industries such as medical and pharmaceutical technology, the food industry, electrical engineering, machine and apparatus construction, as well as analysis, sensor and laboratory technology. Plastics are constantly conquering new areas of application and are increasingly replacing other materials, since they often have essential advantages such as: better sliding properties - chemical resistance - electrical insulation - low weight and others.

Medicine & pharmaceutical technology

Food technology & pharmaceutical technology

Electronics & electrical engineering

Mechanical engineering & drive technology

Analysis & laboratory technology

More applications